Last month we told you how our JEG team on the New Children’s Hospital project in St. James’ campus, Dublin are using the Trimble system to great effect for setting out all the fixing points on the ceiling slabs throughout the building.

There are time savings and efficiencies being proven by carrying out our business in this manner and the learnings are being taken on board across the company. The JEG surveying team preparing to embark on Project Bluejay in Leixlip are now planning to use similar processes for the setting out works on that job.

The Project Team on the NCH project are doing a lot of good work on the ground.

On a recent site visit Construction Manager Paddy Smith walked us through the building and pointed out some of the processes being implemented.

Due to the scale of this project and the similarities between certain areas, if we can improve and refine fabrication and installation processes as we move through the project, we will improve all the time.

Jones local storage cages c/w signage

We have shown before how storing items that are used regularly on sites, close to the place of work can dramatically reduce walking time by the crew.

The NCH team are using standard cages that are readily available from suppliers and adding shelving and lin bins to store pipe clips, unistrut components, pipe fittings for assembly of valve sets etc.

Jones Mobile Cutting Station

As with most large projects these days, BIM is being used for design of the building and services within.

The level of detail provided from the BIM model allows the team to select the supports within a particular area and produce a cut schedule which is sent to the Unistrut supplier.

The supplier then cuts each section of channel and t-rod to length and marks it.

All channels have end caps fitted and are packaged onto a pallet and delivered to the correct area for installation.

Diagonal bracing at anchor point for steam

This system has been used recently on the Grifols project in Grangecastle and was featured in LEAN Times 75 in May of this year.

On the NCH project it is being used for main utility piperacks. The picture below shows an installed rack at basement level carrying Steam and other services.

As with all Steam systems, stress analysis calculations have to be carried out to determine where anchor points and guides need to be positioned. Anchor locations specifically have to be designed into the support structure and diagonal bracing elements can be seen in the photo above to provide a rigid fixing point for an anchor shoe.

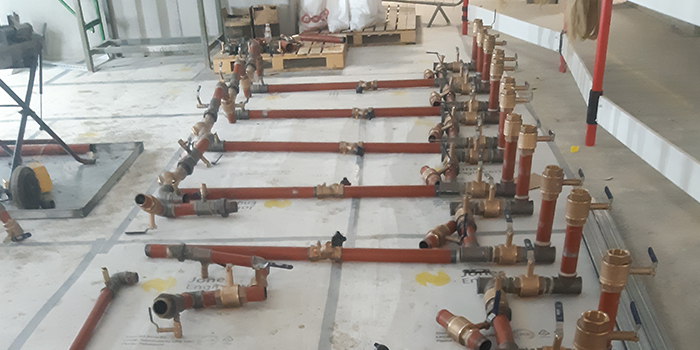

Threaded components being assembled

Anywhere assemblies can be standardised on this project, our BIM team are following this principle. By standardising components and assemblies, we reduce the risk of error and increase efficiency for the fabrication teams.

The picture above shows multiple identical valve stations being fabricated.

We do need to be careful to keep our “batch” size to a manageable level when doing this kind of work.

If the batch is too large and cannot be completed by end of the shift/end of the week etc. there is a danger that parts may go missing, or may have to be moved to allow access, therefore costing us some of our efficiency.

Prefabbed valve set delivered to site c/w Unistruct supports

Prefabbing of assemblies off site is a better solution where possible and the team have set up jigs to the correct dimensions of the connections on the Air Handling Units, allowing them to fabricate all the control valve sets offsite in a workshop environment.

Mock up piperack modules in basement

Piperack modules will form a significant part of the overall project in NCH. A lot of effort has gone into the detail of the modules to standardise their design, so similar attention needs to be paid to the installation method.

First of a kind modules have been built, moved in, erected and joined together to gather data on all of these activities and look for improvements where possible.

For many years our welders have marked each weld with an identifying mark for traceability.

The NCH team are using Victaulic joints instead of welds on many systems and decided to maintain the same level of traceability. An ID label that has space for two signatures is placed at each joint. First signature is for the person who formed the groove and second signature is for the person who fitted and tightened the clamp.