Jones Engineering were recently asked to facilitate a visit from a group of 30no. German Engineering students under the guidance of Prof. Siri Krauss & Prof. Claus Nesensohn. The students are currently studying Lean as one of the modules on their course.

We arranged to show the group around the Guinness brewery in James’ Street and explained how Jones Engineering form an integral part of the daily planning system used by Diageo to co-ordinate all site activities, without interrupting the brewing process.

Tom Horan of Diageo very kindly agreed to act as tour guide for the group and did a great job of explaining :-

Jones Engineering have worked on the Guinness site for over 50 years and have seen many changes over this period, but the current system of planning and operating is certainly the most efficient to date.

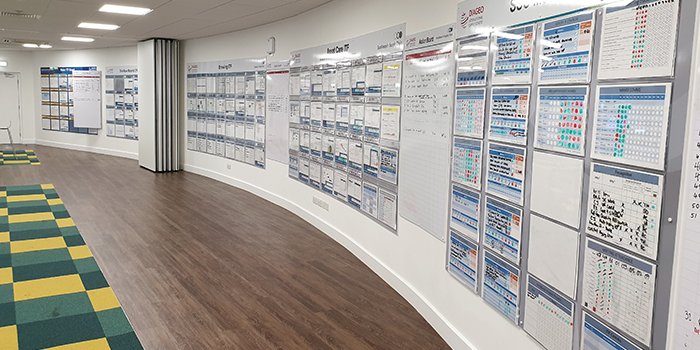

The objective of the planning boards used on site is that a ‘’Visitor’’ must be able to assess how the plan is preforming from the layout of the board in less than 3 minutes.

There are three types of board in use on site (TIER, DOR & ITF):-

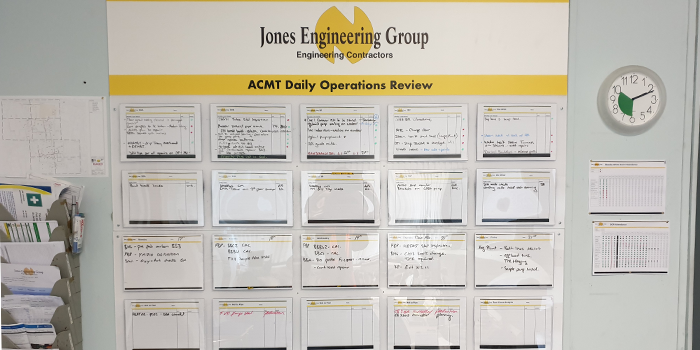

The HAON DOR (shown above) is what Jones Engineering use on site at the morning meeting with the ACMT. It’s held at 8.05am every work morning and attended by all ACMT members. It lasts no more than 5mins and runs through the plan for the day and the review of the work completed yesterday. This board is updated by Paddy Kenna (Jones Supervisor) in advance of each meeting listing any changes to the planned works or any safety items that need to be highlighted.

A weekly meeting is also held using the same board (plus another one) and this lasts 20mins. This is attended by a representative of each craft division on the ACMT (Mech, Elec, I&C, Condition Monitoring, Jones Site Supervision, Jones Health and Safety rep, Jones Management and engineering team. This meeting reviews each area on site maintained by the team and gives updates on upcoming works and project details. It is used to track Audit schedules and highlight/discuss any issues attendees may have or need assistance with. It also gives a look ahead at planned works and outages so each team can be aware of upcoming works that could benefit each area, (it helps for maintenance and project teams to understand each other’s plans).

Some of Diaego’s TIER 1-4 and DOR boards

Any site operating a similar system and promoting good communication between teams will notice productivity improvements.