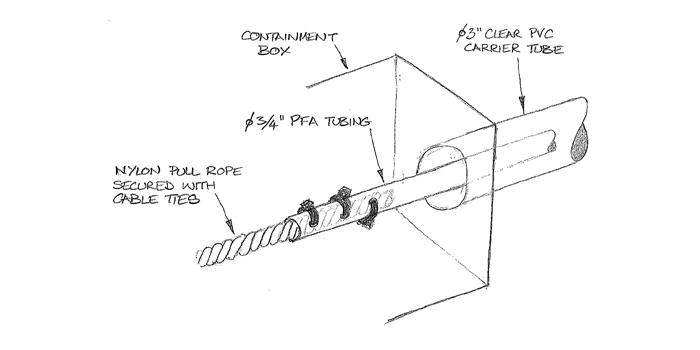

Existing method

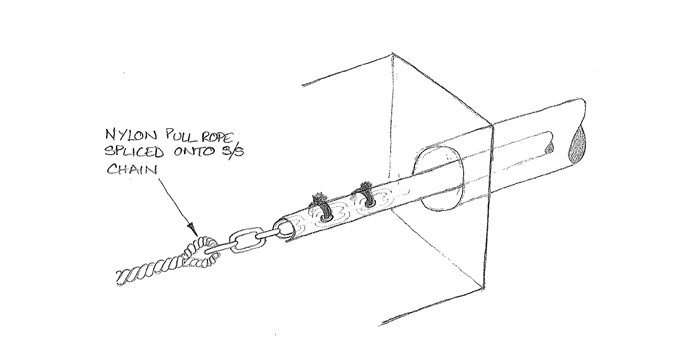

Improved method

It’s the little things that make a difference

As part of the mechanical scope on the Intel project, the crews have to install long runs of small bore PFA tubing that are used to supply chemicals to the different process equipment throughout the factory. Due to the dangerous nature of some of the chemicals, the PFA tubing is installed inside a clear PVC pipe (secondary containment) which acts as a safety feature to contain any leaks should they occur. Some of these runs of tubing can be over 100m in length and so pulling the PFA line into position through the PVC pipe can be difficult to achieve without damaging the high purity tube.

Existing method:-

Normally the crew would have used a nylon pull rope inserted into the PFA tubing and drilled and cable tied through the tubing to secure it in position.

Issues:-

Drilling the rope caused points of failure and led to ropes breaking Time wasted remaking connection and pulling tubing again

Improved method:-

A new method was suggested that involved using a small length of stainless steel chain spliced onto the end of the pull rope and inserted into the PFA tubing.